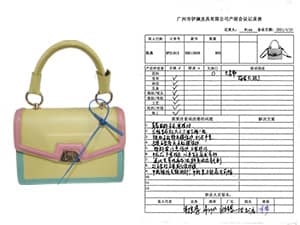

Handbags made in China hold different quality standards in different bag factories. You may often meet quality problem if your source factory is from Yiwu or Hebei, while factories in Guangzhou will be more assured.

Yilan is a top quality brand factory offers on bags in Guangzhou, our quality standards meet AQL 2.5, BS 5131-5.11-1981 (By British Standards Institution) and other popular handbag quality standards.

We have special in-house quality assurance team to ensure your orders finished with good quality performance.

3 Rules to Ensure High Quality

Final inspection procedure is the key step during whole production process, also the most important point of quality control.

All members must be careful women & with 5+ years experience on bag manufacturing industry. They have special working table and well-lit working environment. Each bag will be carefully reviewed & tested by them. Rejected product will be marked & returned to fix defects.

Trusted QC team makes trusted bag quality.

Quality Control Methods & Steps in Yilan

Method 1: pre inspection on material & panels

- all fabric will be inspected when they arrive warehouse

- hardware will be inspected in warehouse by QC

- panels with oil painting will be inspected by QC before stitching or fixing piece by piece

- panels with special treatment will be inspected before putting on line like: nail stud, laser cut, embroidery …

Method 2: protective packaging

- all metal must cover PE protective film

- all oil painted panels must be covered by plastic pipe

- chain strap must be put in plastic or foam pipe

- metal puller should be covered by foam paper

- light color or patent PU must be protected in polybag during producing

Method 3: pre-production sample & pre-production meeting

- a pre-production sample from production line leader in bulk material is required for each order

- pre-production meeting must be hold prior to any sewing

- meeting participants must include salesman, order operator, factory manager, line leader, QA manger

- questions in meeting record must be revised or proceeded by related participants

Method 4: inline inspections by related staffs

- stitching unit leader must check producing hourly

- factory manager must review all production lines 4 times per day

- order operator must follow up production status every day and report to sales team

- QA team leader inspects each procedure every day

Method 5: final inspection

- each bag must pass final inspection before packing

- check outer workmanship & function accessories: zipper, snap, magnet, lock, buckle, pocket …

- inspect lining stitching, inner zipper, care labels, brand labels …

- mark & class bags with different defects and return to revise

Are you looking for a quality assured bag vendor?

Yilan is the right factory you need.

Reach us today to avoid future quality issues in your business. Our contact person will reply you at the first time.